Martensitic transformation (MT)

Introduction

When it comes to solids, a martensitic transformation is a polymorphic phase transition done by altering the crystal structure in the solid state that is athermal and diffusionless.

Due to its incredible strength and hardness, martensite is one of the most important microstructures in steel. martensite is formed in carbon steels by rapidly quenching iron (austenite form) at low temperature. martensite is a supersaturated solid solution of carbon in iron that was called after Adolf Marten, a German metallurgist.

The hardness and strength of carbon steel improve as the amount of martensite in the steel increases, but the toughness of the steel diminishes. These effects are primarily influenced by the amount of carbon present in the steel in question.

Simulation setup

A built-in example, "Martensite C01", in OpenPhase®, simulates the martensitic transition in low carbon steel. Steel has been used as the model material, and it has 2 wt% Mn and 1 wt% Cr and various carbon percentages that can be specified.

The austenite is assumed to be heated to 950 degrees Celsius before being quenched to room temperature at a continuous cooling rate of 100 degrees Celsius per second, which is incorporated in the simulations.

A randomized nucleation technique is used, which chooses two random martensite variations from all available martensite variants each time a new nucleation site is formed. In order to distinguish between different martensite variants, the indices of these variants are denoted by notations derived from Kurdjumov–Sach (KS) orientation relationships.

In the file "ProjectInput.opi", you can find all the input parameters that are relevant to the simulation. All of the simulation parameters can be found in the referenced document [1].

Results

It is necessary to use a constant cooling condition to simulate the experimental quenching process accurately. Higher temperatures above the martensitic start (Ms) temperature cause randomly distributed nuclei to become dormant because the driving force is insufficient to keep them active. When the temperature drops below Ms temperature, The martensitic phase transformation is activated by the change in chemical driving force over elastic energy penalty generated by the transformation strains.

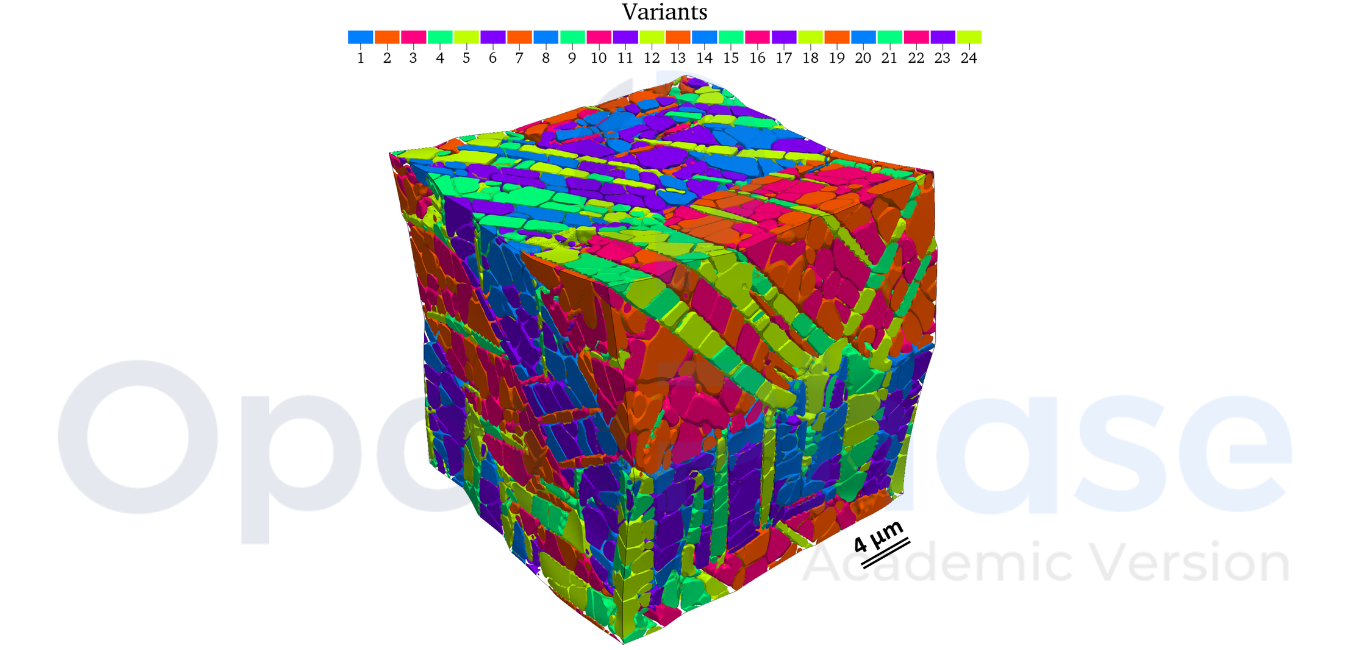

Illustration of the three-dimensional representation of simulated Martensite microscopic microstructures in Figure 1. According to the image, the resulting microstructure displays regular combinations of unique K-S variants in a lamellar arrangement, in which K-S variants with the same Bain strain grow together form blocks.

Figure.1 Simulated martensite microstructure in low carbon steel consisting of 24 Kurdjumov-Sachs symmetry variants.

Related Topics